Introduction:

In

various industrial sectors, maintaining the right temperature is crucial for

both equipment longevity and operational efficiency. Industrial air-cooled chillers play a vital

role in ensuring that cooling needs are met effectively and efficiently. These

chillers are used in a range of industries, from manufacturing and

pharmaceuticals to food processing and HVAC systems. This blog explores the

significance of industrial air-cooled chillers, how they work, and their key

benefits and applications.

What is an Industrial Air Cooled Chiller?

An

industrial air-cooled chiller is a mechanical refrigeration system used

to cool large spaces, machinery, or processes. Unlike water-cooled chillers,

which use water as a cooling medium, air-cooled chillers rely on air to remove

heat from the refrigerant inside the system. The basic operation of an

air-cooled chiller involves circulating refrigerant through a compressor,

condenser, and evaporator to absorb and expel heat, thereby cooling the desired

area or fluid.

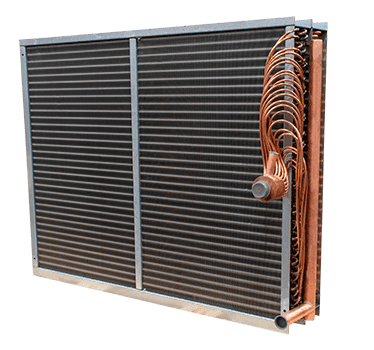

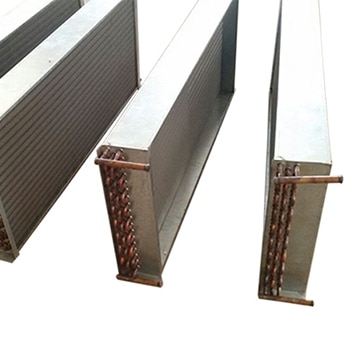

In

air-cooled chillers, the condenser, which is a vital component of the refrigeration

cycle, is cooled by ambient air. This is done through fans that blow air across

the coil, ensuring the heat is efficiently dissipated into the atmosphere. The

chilled liquid produced by the system is then used to cool equipment or spaces.

How Do Industrial Air Cooled Chillers Work?

The working process of an air-cooled chiller involves several steps:

1.

Compression: The chiller’s compressor

compresses the refrigerant gas, raising its temperature and pressure.

2.

Condensation: The high-pressure refrigerant

gas flows through the condenser, where it is cooled by the surrounding air

(blown across the condenser coils by large fans). As it cools, the refrigerant

gas condenses into a high-pressure liquid.

3.

Expansion: The high-pressure liquid

refrigerant is then expanded through an expansion valve, lowering its pressure

and temperature, preparing it for cooling.

4. Evaporation: The low-pressure refrigerant enters the evaporator, where it absorbs heat from the liquid or space that needs cooling. As the refrigerant absorbs heat, it evaporates and returns to the compressor, continuing the cycle

Applications of Industrial Air Cooled Chillers

Industrial

air-cooled chillers are versatile and can be used in numerous industries. Some

common applications include:

- Manufacturing: Industrial processes often

generate heat that needs to be dissipated. Air-cooled chillers provide an

efficient way to maintain optimal operating temperatures for machinery,

production lines, and equipment.

- Food and Beverage Processing: Chillers are used to cool

production processes, storage areas, and refrigerated transport systems.

Maintaining the right temperature is essential for food preservation and

quality control.

- Pharmaceuticals: In the pharmaceutical

industry, precise temperature control is critical for the production and

storage of medicines. Air-cooled chillers ensure a consistent and

controlled environment for sensitive products.

- HVAC Systems: In larger commercial and

industrial buildings, air-cooled chillers are used to maintain comfortable

indoor climates, particularly in buildings with extensive cooling needs,

like hospitals, data centers, and shopping malls.

- Chemical Processing: Many chemical processes

require cooling to prevent overheating. Air-cooled chillers are used in

these applications to ensure the safe and efficient operation of

industrial plants.

Conclusion

A

dependable, cost-effective, and low-maintenance option for temperature control

in a variety of industries is provided by industrial air-cooled chillers. These chillers are essential to industrial operations

because they can be used to cool production processes, preserve food quality,

or keep huge commercial spaces pleasant

For

businesses looking to invest in a high-quality, efficient air-cooled chiller

system, Enggtemp Innovation Pvt. Ltd. offers state-of-the-art solutions

designed to meet the specific needs of various industries. With a focus on

quality, reliability, and performance, Enggtemp Innovation Pvt. Ltd. ensures

that your cooling requirements are met with the best technology available,

helping to improve operational efficiency and reduce energy consumption.